Engineering Reuse Time Savings Calculator

Fill out the form and get the calculator!

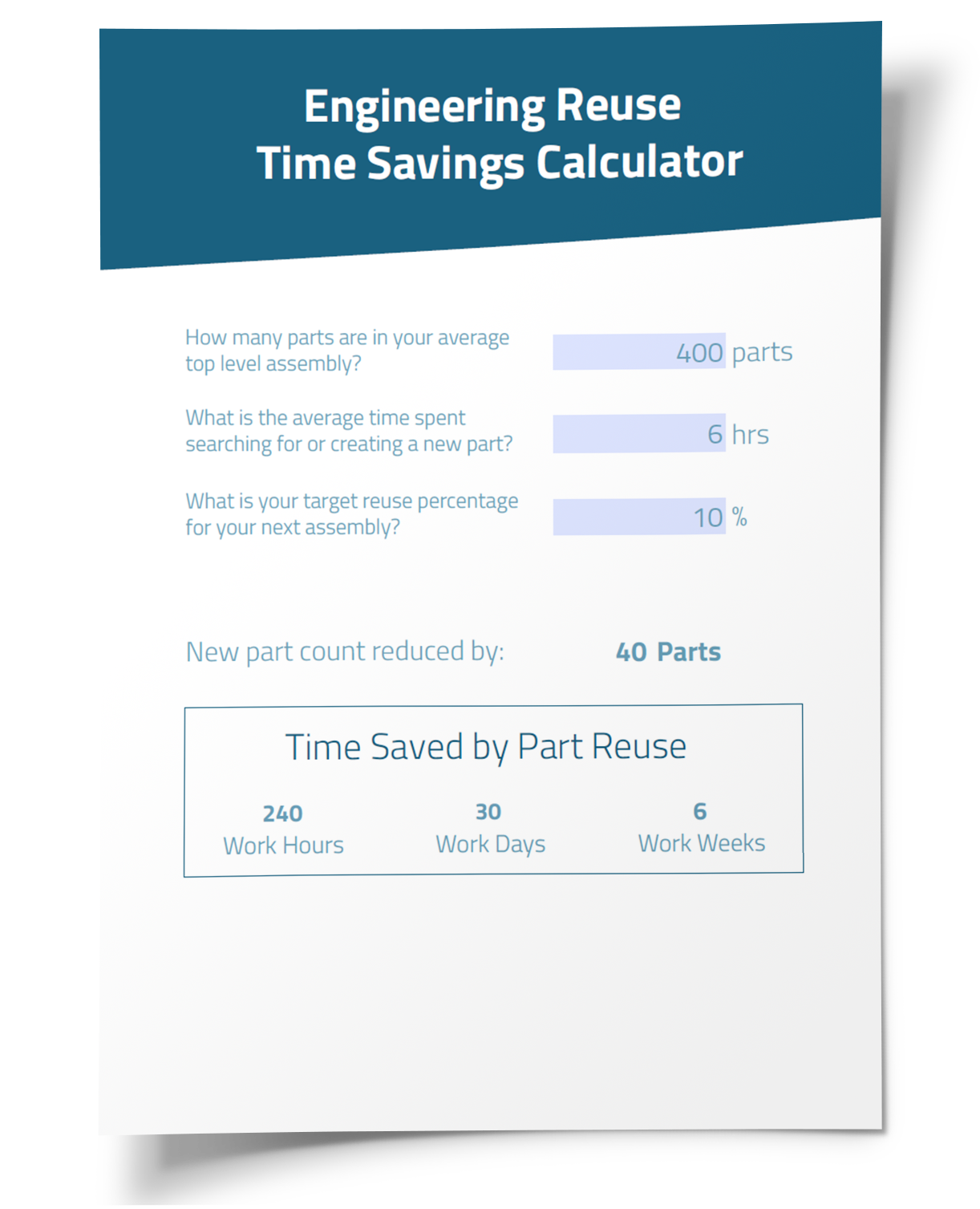

The engineering reuse time savings calculator helps engineers better manage their time. The calculator intends to effectively assist you in calculating how much time you save by reusing parts instead of producing new ones. By using this tool, you can determine how much time can be saved by reusing elements.

There are three components to it. First, type in how many parts are in your average top-level assembly. Using this for the calculation helps set up the equation to determine the number of parts used daily.

For example, say there are 400 parts. You would then type the average time spent searching or creating a new part. Let’s say it takes you six hours to make one part. Adding this number lets you see how much time is allocated for creating parts.

Lastly, you type in your target reuse percentage for your next assembly. Let’s use 10 percent. The target reuse number is what your goal would be for how many parts you reuse rather than creating new ones.

Then, after you enter those three numbers, it produces several calculations. These calculations will ultimately help you to determine the time saved. It tells you what the new part count is reduced by because of parts reused. In our example, it was reduced by forty parts. What this means is that forty parts were saved and reused.

It tells you the time saved in hours, workdays and weeks. In our example, we saved 240 work hours, 30 workdays and six work weeks.

The calculator aims to help you efficiently determine how much time you save by reusing parts compared to creating new ones. This tool saves you time and enables you to calculate how to save time by reusing parts.